Molding Products

Nisshinbo, Japan’s leading fan

maker

— Exceeding expectations

Nisshinbo, Japan’s leading fan maker

— Exceeding expectations

-

1

Customers rank Nisshinbo as Japan’s leading fan maker.

-

2

Our strengths are knowledge regarding revolving part technologies, start-up control abilities, and quality.

-

3

We can provide integrated support from die design to molding and assembly.

-

4

We have numerous overseas bases and can meet customers’ local procurement needs.

Fans for Residential and Commercial Air Conditioners

Nisshinbo provides various molding fans utilizing reliable revolving part technologies

We offer a variety of fans for use in residential and commercial air conditioners, as

well as an extensive range of household appliances, such as refrigerators, air

purifiers, bathroom heating equipment and exhaust fans, and water heaters.

We can

assist at every stage of the process from fan development to manufacture. We can also

support prototyping.

We also offer specialty fans, such as products with special

heat-resistant (material) specifications.

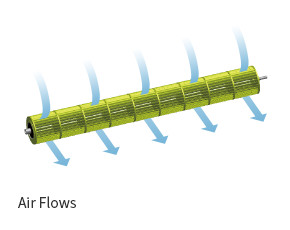

Cross flow fans: Available in outside diameters of 30–120 mm and lengths of 1,000 mm or

more.

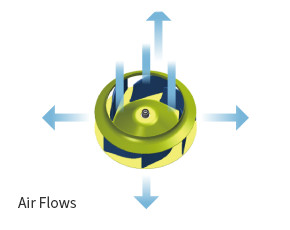

Sirocco fans: Available in outside diameters of 30–400 mm.

Propeller fans:

Available in outside diameters of 30–900 mm.

Turbo fans: Available in outside

diameters of 30–500 mm.

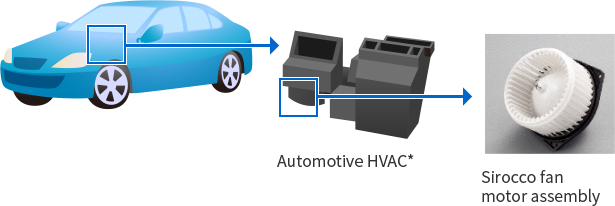

Fans for Automobile Use

Nisshinbo provides fan assemblies for car air conditioners, as well as radiator fans.

Our products are used in air-conditioner blower units for automobile use. You can also find Nisshinbo’s technology for revolving products in sirocco fan assemblies and cross flow fan motor assemblies, where it helps create a more comfortable vehicle temperature environment.

Eco Series

Lighter and energy-saving!

Eco CROSS® Patent acquired

Eco CROSS® is a fan for residential air conditioning that fuses our proprietary revolving part technologies with cutting-edge molding technologies and reduces fan blade thickness by approximately half compared to previous products. This makes the fan lighter and achieves energy savings, and the high creep characteristics make longer fans possible. In addition, durability is enhanced by improving the glass orientation of the blades.

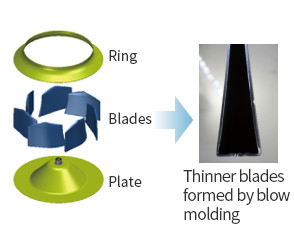

Eco BLADE TURBO® Patent acquired for manufacturing method

Eco BLADE TURBO® is a fan used primarily for air-conditioning units embedded in the ceiling. The blades are formed not by injection molding but by blow molding. As a result, the blades are thinner up to the threshold, and the weight is reduced by approximately half compared to previous products. The lighter weight contributes to energy savings.

Assembly

We assemble automobile parts, air-conditioner parts, and other products and can provide integrated support from design to completed products.

* HVAC: Heating Ventilating Air Conditioning

The Nanbu Plastics Group Provides Integrated Support from Planning to Ornamentation Assembly

The Nanbu Plastics Group handles various molding products for the automotive, healthcare, housing, and other sectors. Nanbu Plastics has established a total production system that integrates all processes from product planning and development to die creation, material development, molding, and ornamentation assembly, enabling direct and speedy responses to customer needs.

-

Products for automobiles

-

Products for healthcare

-

Products for housing

Further information on the Nanbu Plastics Group can be found here (Japanese only).