Customized Machines

Giving shape

to customers’ manufacturing

ideas in the automotive,

aviation, and energy

fields

Giving shape to customers’ manufacturing ideas in the automotive, aviation, and energy fields

-

1

Can handle all process elements, including cutting, assembly, molding, drilling, and welding.

-

2

Outstanding track record in labor savings and automation of production lines

-

3

Can also handle large-scale

facilities and mass production lines.

Customized Machines for Automobiles

Balancing machines

These machines automatically measure and adjust the balance of rotating parts in engines and parts used with axles.

Examples of Production and Delivery Experience

- ・Automated balancing machines for crankshafts

- ・Cutting machines for engine blocks

- ・Cutting machines for steering knuckles

- ・Cutting machines for compressor parts

- ・Cutting machines for differential casings

- ・Cutting machines for differential carriers

- ・Multi-axis drill heads

- ・Modification of machine tools manufactured by other companies

Customized Machines for Aircraft

NC controlled pin tables

These devices flexibly fix and hold processed parts according to their three-dimensional configuration.

Examples of Production and Delivery Experience

- ・NC controlled pin tables for aluminum exterior plates

- ・Three-dimensional laser trimming devices

- ・Laminating machines for CFRP*

- ・Molding machines for CFRP*

- ・Large-scale painting equipment

- ・Hole-drilling machines for CFRP*

- ・Large jigs

* Carbon fiber reinforced plastics

Customized Machines for Batteries

Storage battery assembly and processing equipment

This is a production line for secondary and storage batteries used in automobiles and industry. It achieves enhanced product quality and uses cutting-edge technology to automatically and quickly perform metal processing, assembly, welding, and inspection.

Module laminator for photovoltaic modules (In-line specifications)

Our laminators achieve outstanding temperature uniformity and vacuum creation. We have an extensive lineup, including the world’s largest laminator with an effective processing area of 2,300 mm x 4,500 mm.

Examples of Production and Delivery Experience

- ・Storage battery assembly equipment

- ・Storage battery processing equipment

- ・Storage battery welding equipment

- ・Photovoltaic modules laminator

Customized Drilling and Molding Press Machines

Frame processing machines

These machines perform drilling and cutting for H plate and flat plate frames.

Square pipe processing machines

Patented technology is used to drill holes without distortion in the square pipes.

Examples of Production and Delivery Experience

- ・Laser cutters for track frames

- ・Drill presses for track frames

- ・Drilling and cutting machines for H plates

- ・Large-scale transportation equipment

- ・Powder molding presses

- ・Drilling machines for square pipe

- ・Drilling and processing machines for aluminum profiles

- ・Drilling machines for round pipe

- ・Large press brakes

- ・Larger shearing machines

Other Customized Machines

Examples of Production and Delivery Experience

- ・Cylindrical screen welders

- ・Spot welders

- ・Resin spinning equipment

- ・Portable tools for healthcare applications

- ・Special-purpose FMS*

- ・Automobile testing machines

- ・Special-purpose grinders

- ・Various OEM design and production

- ・Large part processing

* Flexible manufacturing system

Manufacturing Capacity

Machinery processing equipment and inspection devices

| Large five-surface processing machine(3m x 1m x 10m) | 1 |

|---|---|

| Small five-surface processing machine | 1 |

| Planer | 1 |

| Machining center | 3 |

| Wire cutting machine | 2 |

| General-purpose milling machine | 1 |

| Electric discharge machine | 1 |

| General-purpose lathe | 2 |

| Surface grinder(7m, 1.2m) | 2 |

| Three-dimensional measuring machine(2m x 1.2m x 1m) | 1 |

| Three-dimensional measuring microscope | 1 |

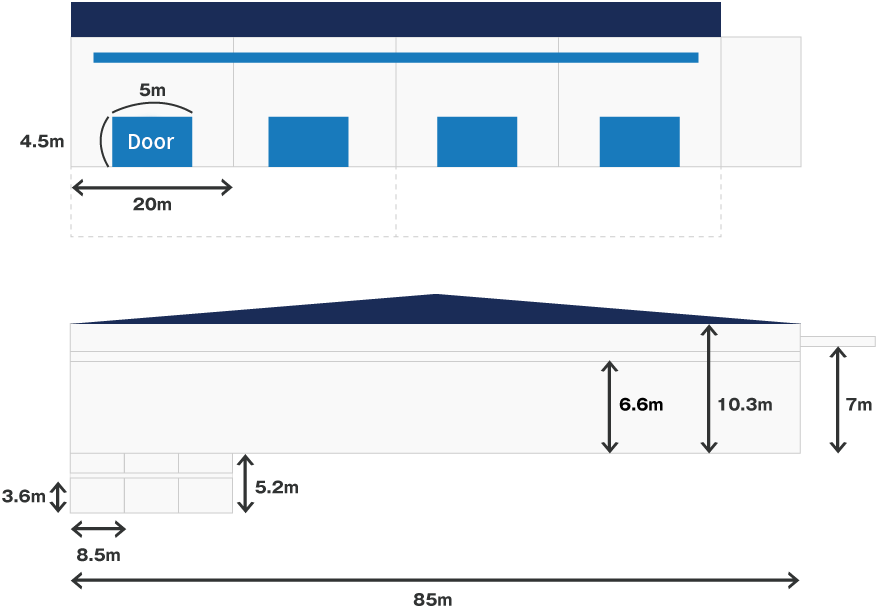

Assembly plant

Product Assembly Spaces

| 1st floor | W 20 m x L 85 m x crane height 6.6 m x 4 lines |

|---|---|

| Basement | W 8.5 m x L 40 m x crane height 3.6 m x 3 lines |

Crane Capacity

| 1st floor | 20 t x 1 unit + 7.5 t x 1 unit (x 4 lines) |

|---|---|

| Basement | 2.8 t x 1 unit (x 3 lines) |